Other news & insights

Company news 26 November 2025

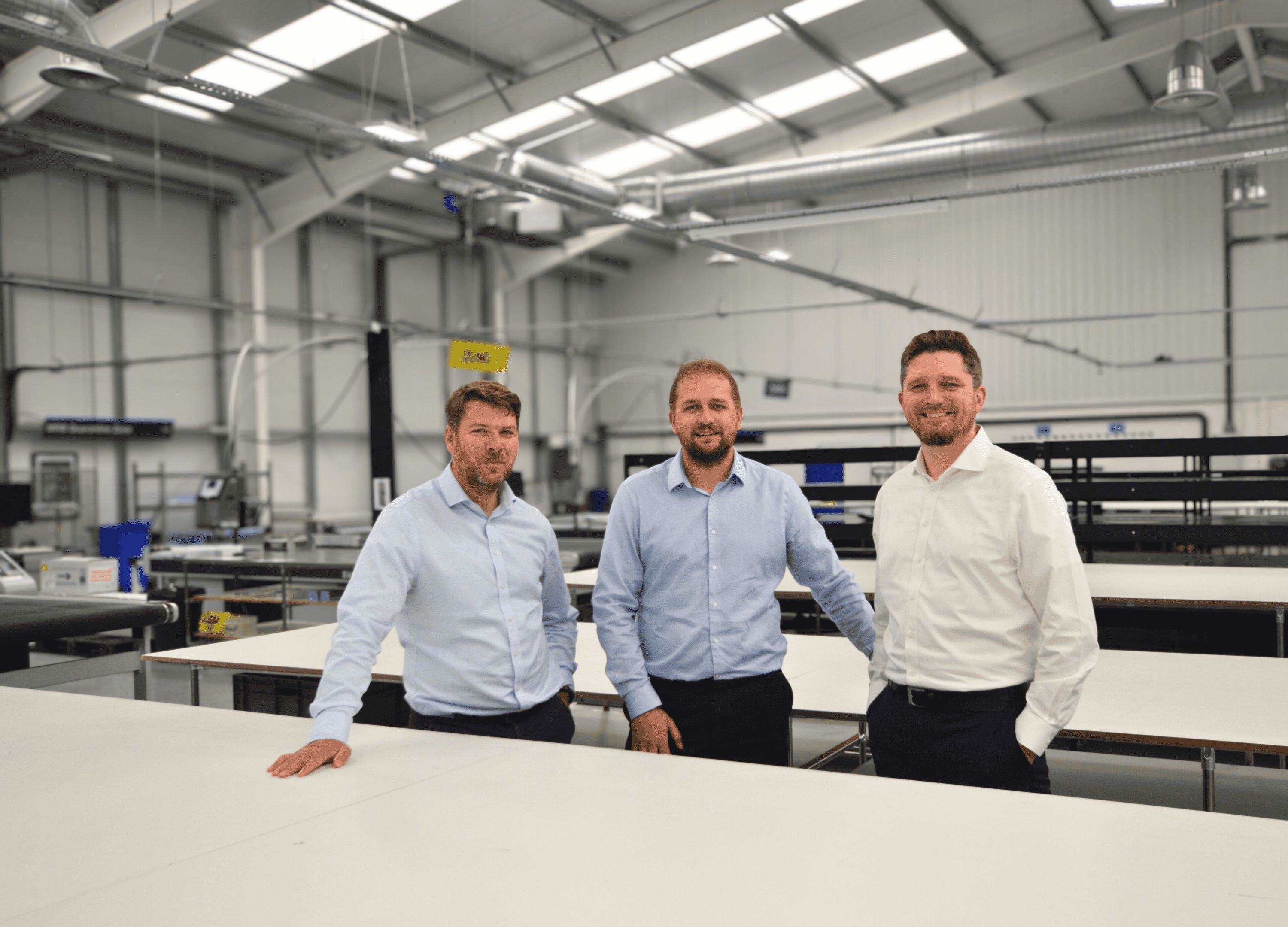

Velocity Composites Shares Thanksgiving Message to U.S. Teams and Customers

Read more

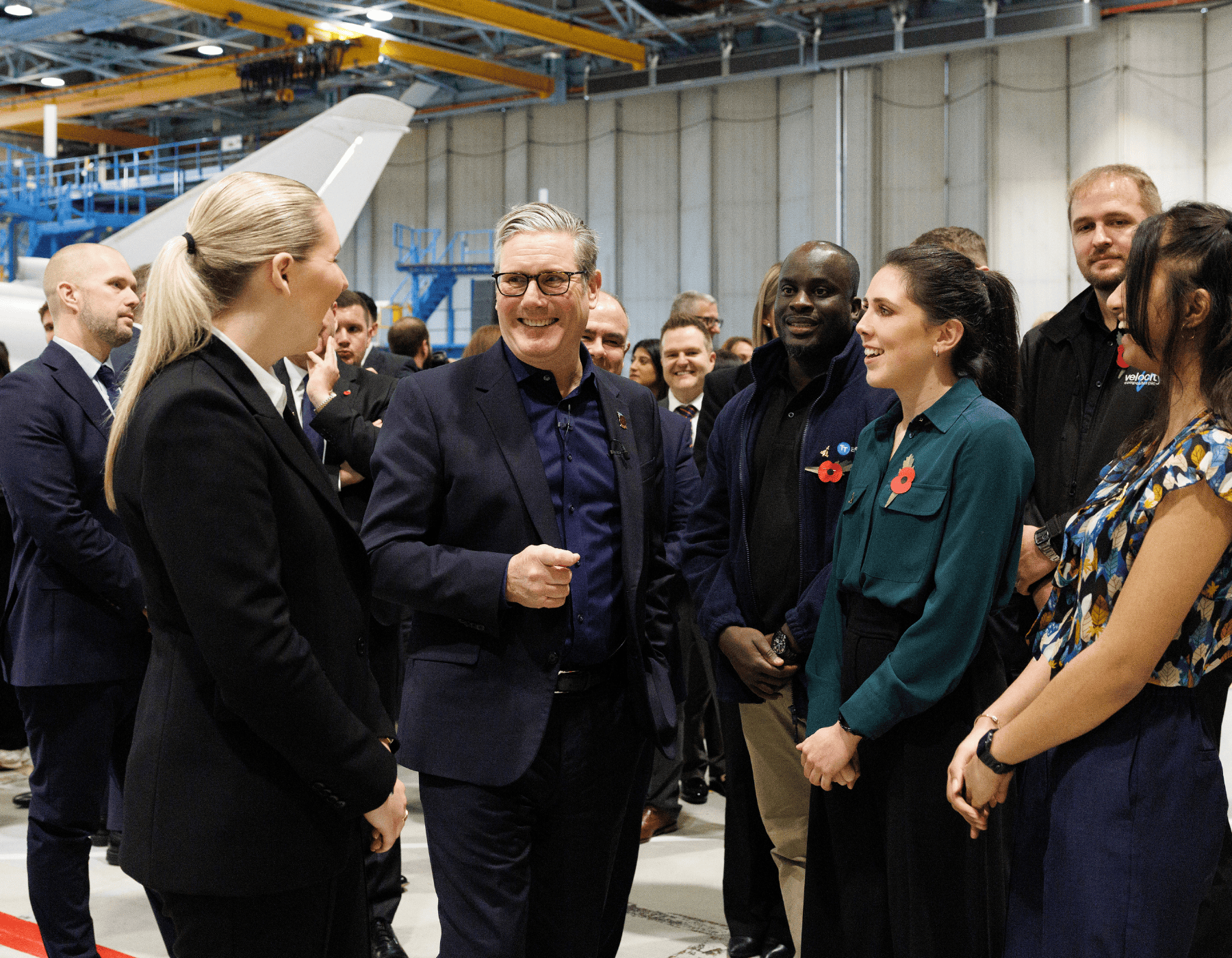

Company news 5 November 2025