Velocity Composites plc, the Burnley-headquartered supplier of advanced composite material kits to the aerospace and high-performance manufacturing sectors, has announced successful recertification for both AS9100 and Nadcap across its entire operations—reaffirming the company’s industry-leading standards in quality, process control, and digital manufacturing. This dual recertification underlines Velocity’s continued focus on operational excellence and traceability as the business expands both in the UK and internationally, with the company’s integrated supply chain solutions increasingly relied upon by Tier 1s and OEMs across civil and defence aerospace programmes.

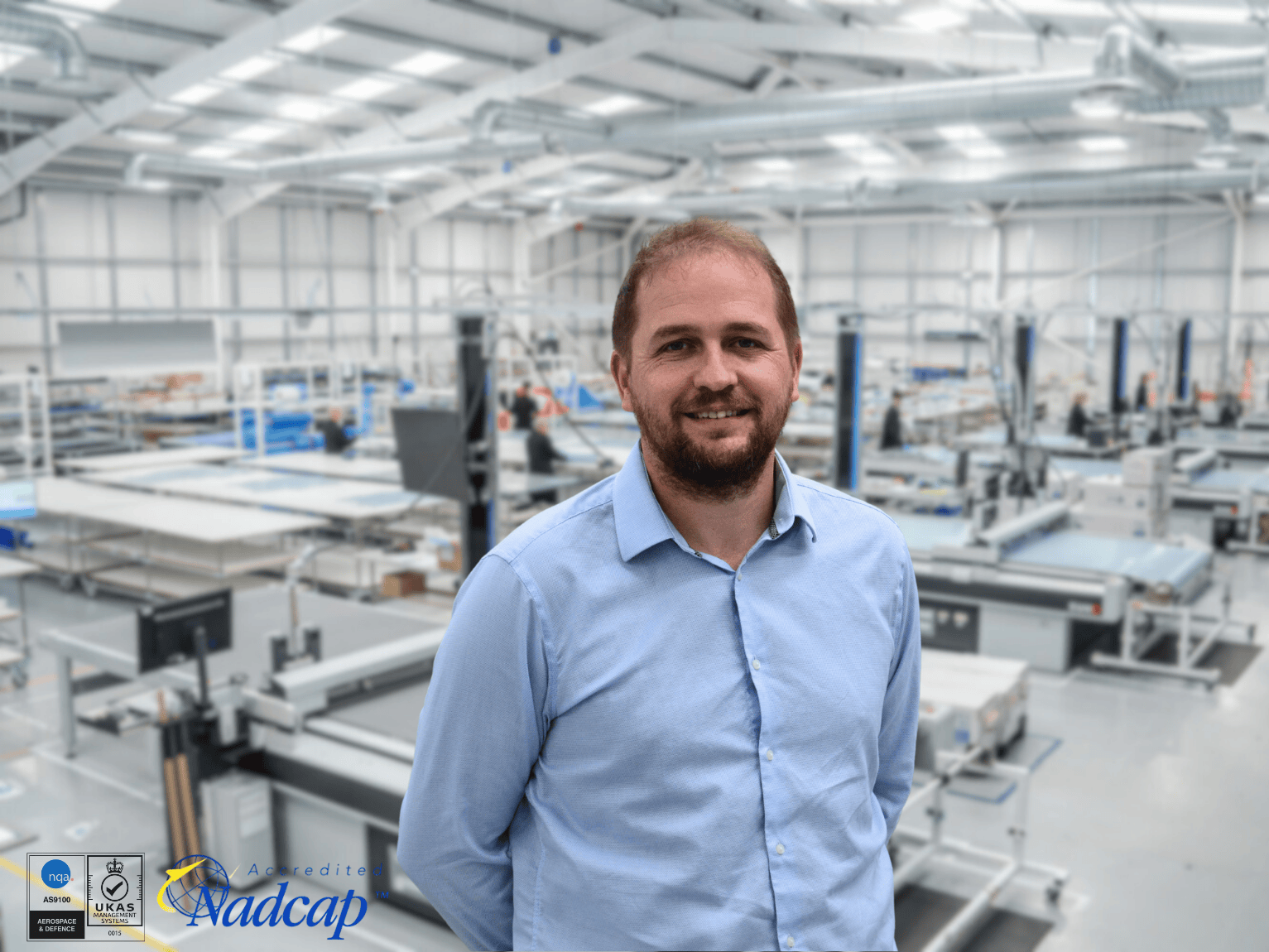

At the centre of this achievement is Sheldon Atherton, Head of Technology and Quality Systems, who has played a pivotal role in embedding a culture of quality and process innovation across the organisation since joining the business in 2008. “Recertification to both AS9100 and Nadcap is a reflection of the discipline, innovation and pride that runs through every part of our operation,” said Atherton. “These are not easy accreditations to earn, and to retain them is a direct result of our team’s ongoing commitment to quality, data integrity and customer-focused performance.”

Sheldon’s journey within Velocity is a homegrown success story. Developed through the company’s own leadership development programme, he has built cross-functional experience across production, systems integration, quality, and supply chain. Today, he leads both the firm’s Quality Assurance function across all sites and the technological development of VRP, Velocity’s proprietary digitised manufacturing and planning system. “What sets Velocity apart is how we link quality to innovation,” Atherton explained. “Our VRP platform allows us to drive improvements in efficiency, schedule adherence, and process control from a centralised, data-driven environment. That digital backbone ensures we remain agile, compliant, and continuously improving.”

The AS9100 recertification confirms that Velocity’s Quality Management System (QMS) meets the rigorous requirements of the global aerospace standard, while the Nadcap accreditation, overseen by the Performance Review Institute (PRI), affirms the company’s technical proficiency and process consistency in areas critical to aerospace manufacturing.

Chief Executive Officer Jon Bridges praised the recertification as a mark of the company’s strategic discipline as it continues to scale in global markets. “These certifications are fundamental to our ability to serve the world’s most demanding aerospace customers,” said Bridges. “They validate the trust that our customers and partners place in us, and they reflect the strength of the systems and people—like Sheldon—who underpin everything we do.”

“As we take on more complex global programmes and grow our footprint in the US, having this foundation of accredited quality and digitised control gives us and our customers a distinct competitive edge as we all deal with production rate recovery, new platform ramp ups and supply chain constraints,” he added.

With operations in the UK and the US—including its Nadcap-accredited Tallassee, Alabama site—Velocity continues to deliver on its strategy to become the aerospace industry’s partner of choice for composite material supply chain solutions. “We’ve built a system that meets today’s expectations and is ready for tomorrow’s demands,” said Atherton. “This recertification confirms that Velocity is looking beyond compliance, to be forward-looking, capable, and trusted.”